100 Discovery Way, Unit 110, Acton, MA 01720 US..

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

Click here for our Die Protection Clinic Schedule

Welcome to Wintriss Controls

We are a leading manufacturer of press automation, die protection, and safety controls for the metal stamping industry, and data collection software for all discrete manufacturing. Our products are known for their proven performance and rugged dependability in the toughest factory environments. Wintriss equipment is backed by attentive service, timely repairs, and comprehensive spares inventories. Our toll-free hotline gives you immediate access to technical support experts for product information and applications assistance.

Process Control

Monitor every aspect of press operation and control and monitor ancillary equipment.

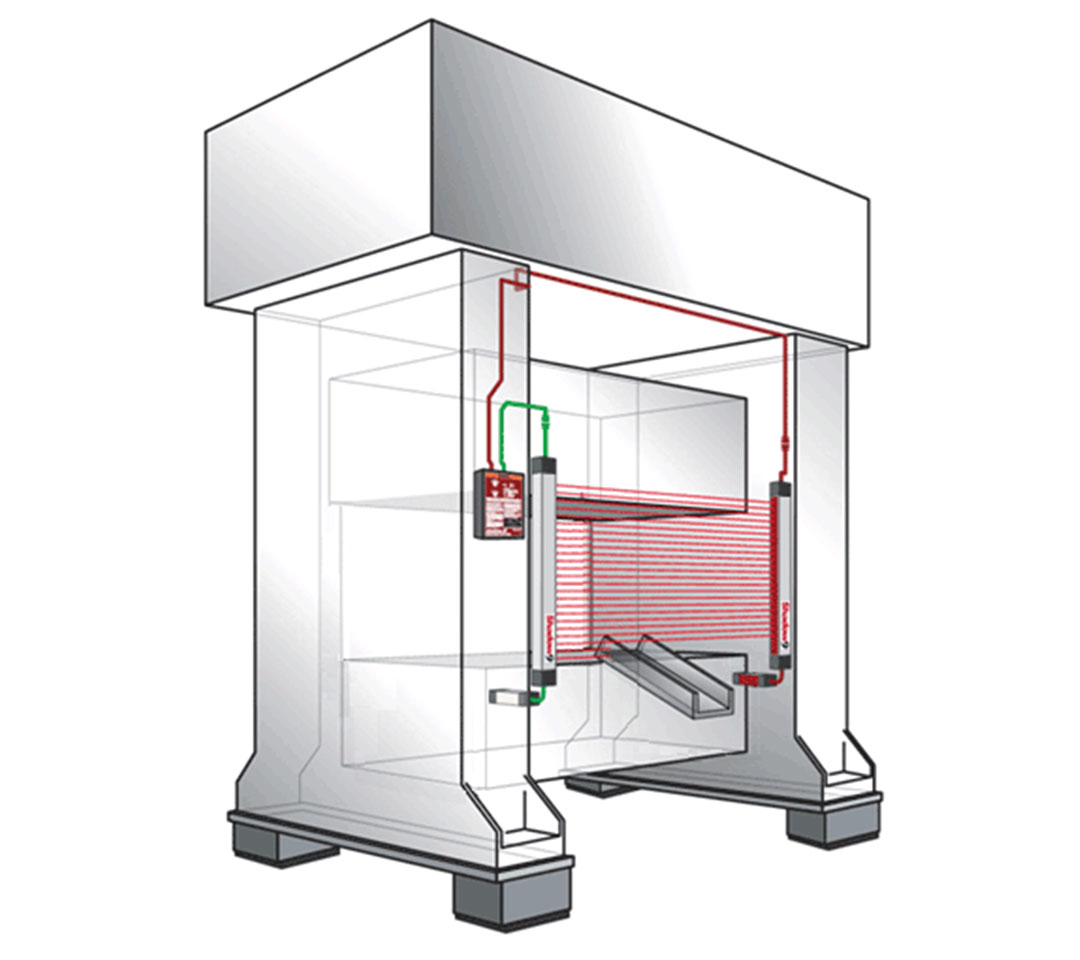

Safety

Safety light curtains and clutch brake controls that meet or exceed ANSI and OSHA regulations.

Integrated Solutions

Wintriss can build you a complete, integrated, turnkey control package, perfectly suited to your needs.

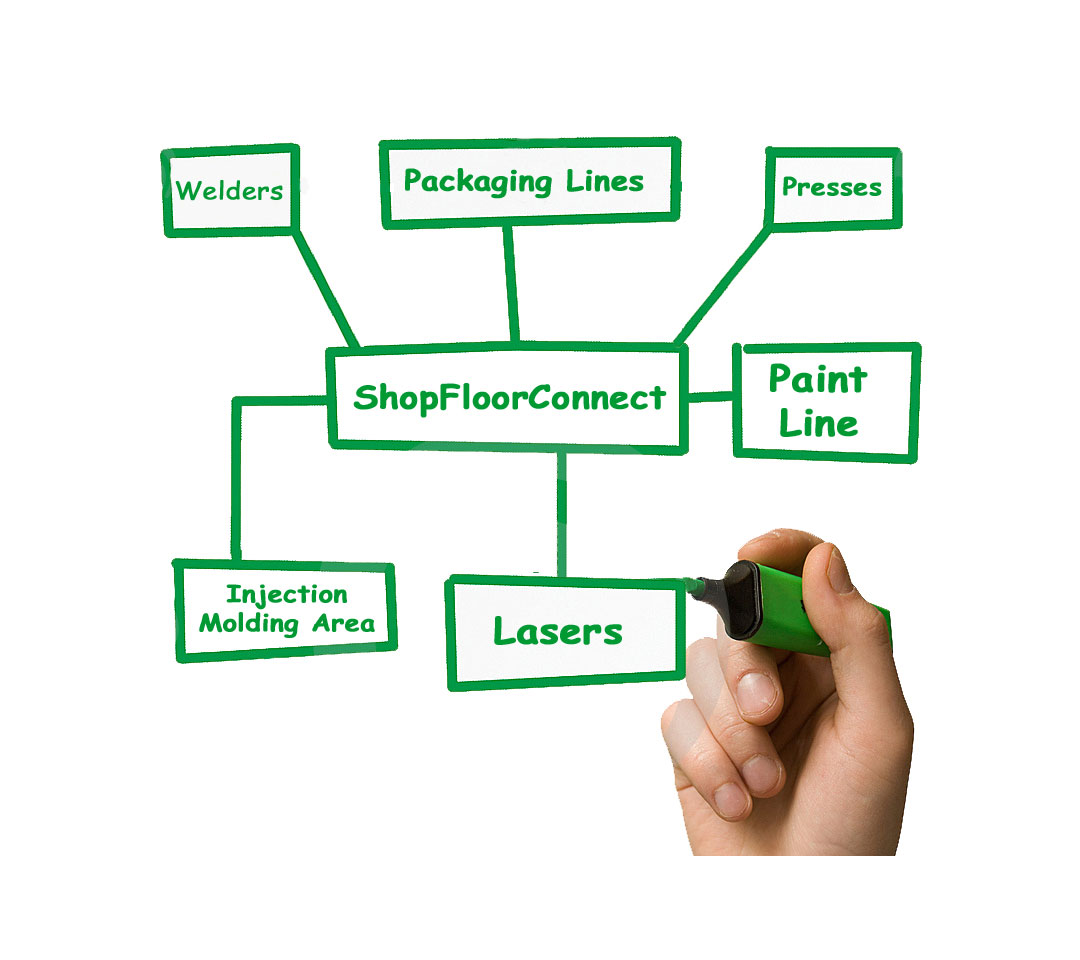

Data Collection

Collect and share efficiency, uptime, downtime, and production data from every machine in your factory.

If you have any questions...

let us help you

Press Automation Controllers

Whether the press is mechanical, servo, or hydraulic, Wintriss can provide a comprehensive state-of-the-art press automation controller.

Discrete Controllers

For simple monitoring applications, Wintriss can provide stand-alone die protections systems and easy-to-use 2 and 4 input tonnage monitors.

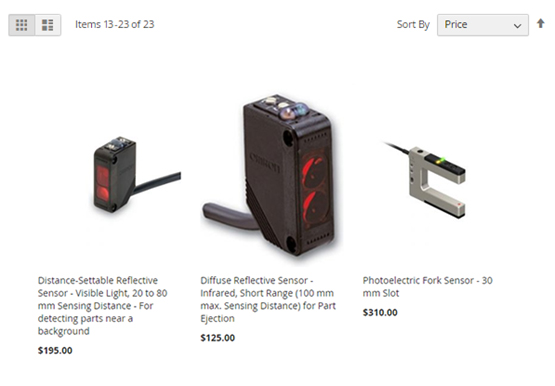

Sensors and Connection Hardware

We offer a complete line of electronic and electro-mechanical die protection sensors, cabling and wiring accessories, and die-mountable junction boxes.

Shadow 9 Safety Light Curtains

Forged from Wintriss's 50 years of experience in the light curtain business, the Shadow 9 is designed for the toughest applications, and made to withstand the rigors of the pressroom, including severe shock, mechanical abuse, and lubricant spray.

Pressroom Compliance Surveys

We will come to your plant, survey your machines, and provide you with a comprehensive complaince report, complete with product and upgrade recommendations. Contact us for details.

Turnkey Control Packages

If you’re updating your press with a new clutch/brake control, adding integrated automation, or replacing the entire electrical package, Wintriss can do it all – from start to finish.

Design Services

We will come to your plant, survey your machines, provide comprehensive mechanical and electrical layout and design services, and include a complete CAD documentation package for all of the equipment. Contact us for more information.

Wonderware ® Integration

We can use SmartPAC PRO's Wonderware integration option to create HMIs for your ancillary automation, making the SmartPAC Pro the only screen you'll ever need to put on your press.

Real Time Data Yields Real Time Results

ShopFloorConnect Asset Utilization Software and hardware automatically collect shop floor production data that is timely, accurate, and unbiased. Best of all, this production tracking system does it automatically, and in real time!

Collect Data from Any Machine

The ShopFloorConnect Machine Interface (SMI 2) connects any machine to the ShopFloorConnect Machine Monitoring Software. The SMI 2 is network-ready and factory-configured to drop right in to your existing ShopFloorConnect installation and begin collecting data.

Integrates With Your Existing Software

ShopFloorConnect has an Application Program Interface (API) web service-based two-way communication protocol that enables ShopFloorConnect to receive manufacturing job schedule information (such as job and part numbers, quantity of parts required, due dates, etc) from your ERP or MES software..

Technical Support

A toll-free hotline gives customers immediate access to technical support experts for product information and applications assistance. Our technical service experts are available from 8:00 AM to 5:00 PM Eastern time. Give them a call at 1-800-586-8324 (select Option 2).

Field Service

Wintriss has technicians around the country that can assist with any of your service needs. Call us at 1-800-586-8324 or contact us to initiate a request.

Training

Wintriss offers a variety of training programs for press operators, maintenance personnel, toolmakers, and engineers.

A new article in FABshop Magazine explores the productivity and efficiency increases that the SmartPAC PRO press controller creates on the pressroom floor.

FABshop Magazine notes that SmartPAC PRO simplifies the automation process by centralizing all of a stamping press's control requirements in one location.

Wintriss Controls Group has entered the world of e-Commerce with our new Wintriss Online Store. Every item in the store has been carefully selected to deliver superior performance in metal stamping applications.

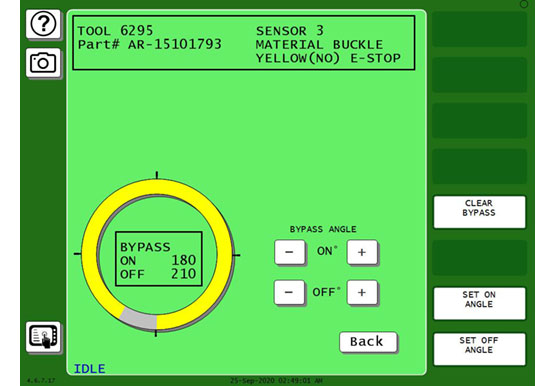

We've introduced a host of new features and improvements for the SmartPAC PRO DiProPAC including a powerful and customizable new sensor monitoring type called the "Green Flex".

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved