100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

SmartPAC PRO PM Monitor

Track important maintenance items at the SmartPAC PRO

SmartPAC PRO's PM Monitor tracks up to 64 maintenance items

When you perform preventive maintenance on your press in the traditional manner, the frequency is based solely on elapsed time. Maintenance items in and around the press are checked daily, weekly, monthly, etc. However, smaller job lots and more frequent tool changes cause varying rates of wear and tear on your press and related equipment. As a result, traditional PM programs can be wasteful or inadequate. SmartPAC PRO changes that!

The SmartPAC PM Monitor lets your maintenance department schedule its time more efficiently. SmartPAC monitors your entire stamping operation and signals a maintenance alert only when something needs to be checked. SmartPAC has the ability to track each item on your list according to actual usage, allowing you to base your maintenance schedule on probable wear and tear, rather than elapsed time.

SmartPAC PRO's PM Monitor tracks each item according to how it is used

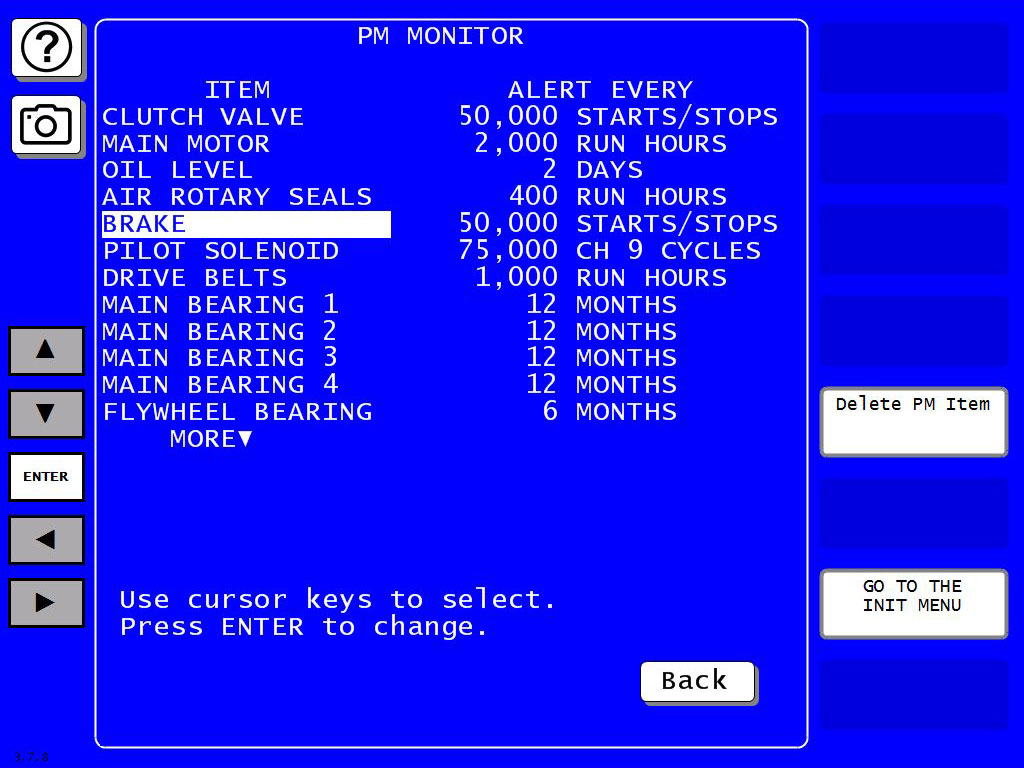

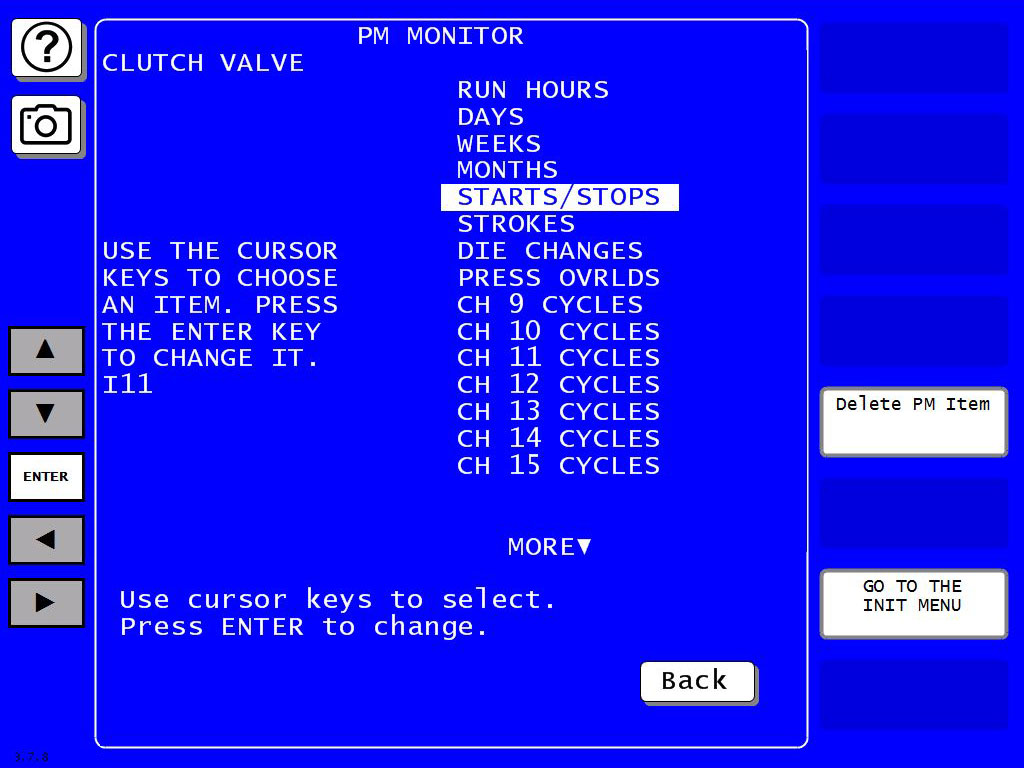

The PM Monitor can track up to 64 scheduled maintenance items. And you can choose different units for each, such as machine starts or stops, press strokes, motor-on hours*, cam channel actuations, die changes, tonnage overloads*, etc., depending on how your SmartPAC is configured.

The PM Monitor also keeps track of hours, days, weeks and months for items that nee d to be maintained according to a time schedule. A frequency is assigned to each item to tell the PM Monitor when to signal an alert.

Because the SmartPAC PRO tracks parameters in addition to time, it can account for abnormally light or heavy usage of your press. For example, a traditional PM program might tell you to check the press braking system every three months. But if your press is idle, or running only continuous coil-fed jobs there will be very little brake wear during the three month period, so any time spent checking the brake would be wasted.

On the other hand, if the press is running mostly hand-fed jobs in the single-stroke mode, the many starts and stops will cause higher-than-normal brake wear, so three months maybe too long between inspections. The SmartPAC PM Monitor can be set to keep track of machine stops and signal a PM alert after, for example, 50,000 machine stops.

The password-protected PM schedule can be displayed in the run mode

The entire PM schedule is displayed in SmartPAC's run mode. The schedule shows each item, its units, frequency, and current value. The display highlights any items on alert status. The alert status remains highlighted until it is cleared and the item reset. The PM Monitor continues to track alert items until they are reset. SmartPAC's PM schedule is password protected to prevent unauthorized personnel from clearing an alert.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved