100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

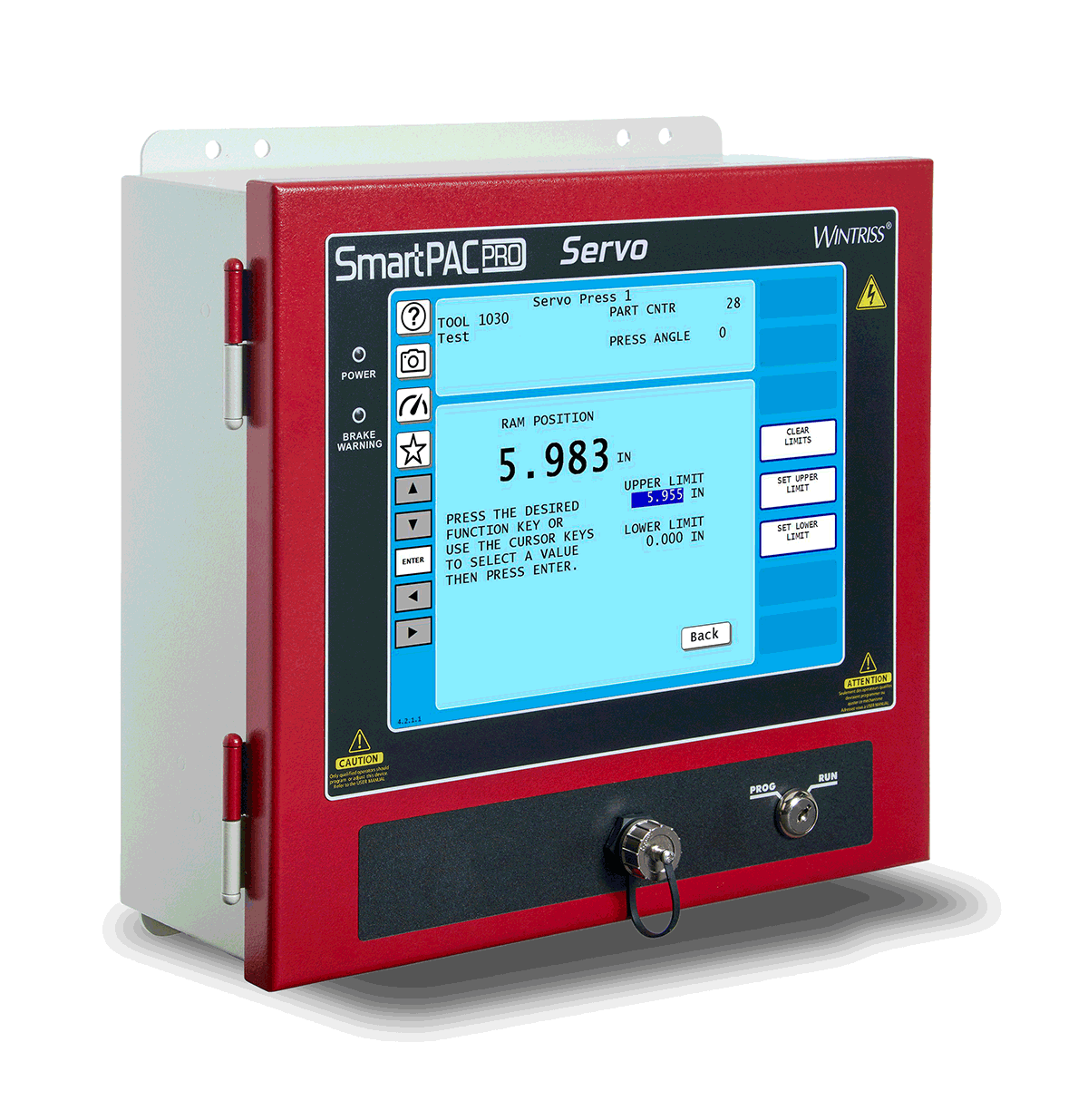

SmartPAC PRO Servo

We've created a version of the SmartPAC PRO with many Servo Press-specific features.

New Features and Capabilities

- The large (12" diagonal) vibrant touch-screen enables efficient navigation and allows more information to be displayed.

- Advanced Job Storage - SmartPAC PRO's searchable Tool Manager can store an unlimited number of tool programs to accommodate even the busiest shops.

- The new Tool Summary Screen enables you to view the entire contents of each programmed setup on a single screen, provides a place for users to place notes for the job, and can be exported to a USB disk as comma-separated values.

- Users can create custom home screen dashboards to display the information they use most often. These dashboards can be named and saved in the favorites menu, and quickly recalled any time.

- Easy-to-access front panel external USB port for backing up tool number memory, capturing screen shots, attaching a bar code scanner, keyboard, mouse, or other USB devices.

- The new Options Manager allows users to add, enable, or disable firmware options without having to upgrade the SmartPAC PRO firmware. Simply enter an activation code, and the option will be initialized

- Enhanced Automation Integration - If you use Wonderware® to create HMIs for your ancillary automation, the SmartPAC PRO's

Wonderware integration option enables the SmartPAC Pro to be the last screen you'll ever need to put on your press.

-

Versatile Installation Options - The main screen/HMI can be separated from the rest of the SmartPAC PRO system, simplifying installation and wiring. The only

connection required between the HMI and the main SmartPAC PRO controller and I/O is a single USB cable.

Wintriss also offers an optional pendant enclosure and pendant arm for added mounting versatility.

SmartPAC PRO Servo mounting options - Enclosure (left) and Pendant Arm (right)

SmartPAC PRO User Configurable Dashboards

Servo Press-Specific Features

- Multiple Stages - SmartPAC PRO Servo can set the upper and lower limits for up to ten stages of motion.

- Self learning feature that allows the operator to run the machine through its programmed stages and automatically capture upper and lower limits for each stage.

- Ability to 'mask' programmable limit switch outputs and die protection sensor inputs for any stage. This allows you to actuate limit switches and monitor sensors only during the stages where they are needed.

- User-selectable resolution curves - The SmartPAC PRO Servo has 5 built-in resolution curves that allow for sinusoidal motion and/or provide resolution as small as 0.001" of linear travel for programmable limit switch outputs and sensor inputs.

- Multi stage information and resolution curves are individually stored with each setup, allowing you to configure your machine differently for each job.

The SmartPAC PRO Servo uses an accurate magnetostrictive linear position sensor to monitor the ram position. The graphical user interface for die protection and programmable cams in the SmartPAC PRO for mechanical presses is maintained by dividing the downstroke from 0° to 180° and the upstroke from 180° to 360°.

Learn about our SmartPAC PRO Upgrade Program

Standard SmartPAC PRO Servo Features and Options

- Powerful counting capabilities, including stroke, parts, batch presets and total hits-on-a-tool

- Password security allows you to protect your settings -- individual settings or all settings

- Run your SmartPAC PRO Servo from your desktop PC with Remote Access.

- Summary screens for sensors and cams. See DiProPAC and ProCamPAC below for details

- Global cams. See ProCamPAC below for details

- Messaging send messages to email and text-enabled pagers/cell-phones

- Built-in backup and restore capability. You can save a copy of SmartPAC PRO's setup memory and initialization setting on your network, and restore it to the SmartPAC PRO when needed.

- Easier Firmware Upgrades - No chips to change when you add new features. SmartPAC PRO firmware can be upgraded through the built-in USB port. Firmware options can be added by entering a code.

- SmartView PRO press status from anywhere in the world

- Enhanced Error/Event Log time stamped detailed information for 200 most recent errors/events

- Enhanced Diagnostics status of inputs

- Easy to upgrade from SmartPAC 2 Servo! All of your existing optional PAC modules, linear sensor, DSI, cam outputs, SFI, and other connections go directly into SmartPAC PRO! All your existing setups can be transferred to the SmartPAC PRO; ask your Wintriss Rep to help.

- The Info Center option allows SmartPAC PRO to display setup sheets, drawings, photographs, and other information right at the press.

- DiProPAC 8, 16, or 32 sensor die protection module prevents costly downtime, damage and die repairs by providing timely feedback, control and advance warning of potential problems.

- ProCamPAC 8 or 16 channel programmable cam (limit switch) module

- AutoSetPAC 2 or 4 point load analyzers monitor press tonnage and load conditions

- Servofeed Interface (SFI) allows you to interface to popular brands of servofeed controls.

- PM Monitor tracks up to 64 maintenance items and alerts you when each is due.

- Multilingual Menus (English to Spanish, German, or Portuguese) run mode for Status and Adjust menus.

- Custom Consoles and Panels combine any and all controls, motor/starter options, touch-control buttons, etc., in a compact, fully integrated workstation.

- Wintriss ShopFloorConnect® Manufacturing Data Collection Software automates the on-line collection of operating data from the SmartPAC PRO Servo and every other machine in your plant.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved