100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

Know Your Critical Angle

The critical angle is the last point in the crankshaft's rotation where a stop can be signaled so that the ram stops before the die closes. Since the whole goal of die protection is to stop the press before a bad hit can occur, knowing the critical angle for every die is, well... critical.

If your press is equipped with a SmartPAC, you're in luck. Determining the critical angle is easy:

- Load the die in the press, and inch the press to observe and record the die closure angle.

- Disable the sensors, and with no material present, run the die at its normal operating speed. If your press is equipped with a tonnage monitor, you'll have to recalculate the setpoints before you start in order for it to let the press run empty.

- Select "BRAKE MONITOR" from the SmartPAC's run mode.

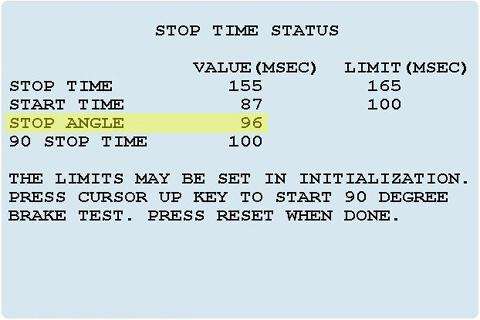

- Press the cursor "up" key to perform a 90° stop time test. This will signal the press to stop half way through the downstroke, where the brake has to work the hardest to stop the machine. This will give you the "worst case" stopping performance.

- When the press stops, record the STOPPING ANGLE shown on the Stop Time Status screen (highlighted below).

- Subtract the Stop angle value (from Step 5) from the die closure angle (observed in Step 1) to get the critical angle.

SmartPAC Brake Monitor screen shown with Stop Angle highlighted

Remember - the ready signals for your cyclic (Green) sensors should end before the critical angle to ensure that the press will stop before it makes a bad hit.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved