100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

The History of Wintriss

Wintriss Manufacturing was founded in the 1940s by George Wintriss as a manufacturer of machinery and metal stampings in New York City. The company specialized in making small spring steel reeds that were used in things like duck calls and children's toys. Wintriss patented many of the products, some of which are quite strange. By the mid 1950s, the company shifted focus to the nascent electronics industry. George Wintriss applied for a patent for the first electronic die protection system in 1957, and the company changed its name to Wintriss Controls. The rest as they say, is history. Here's a timeline of significant company milestones:

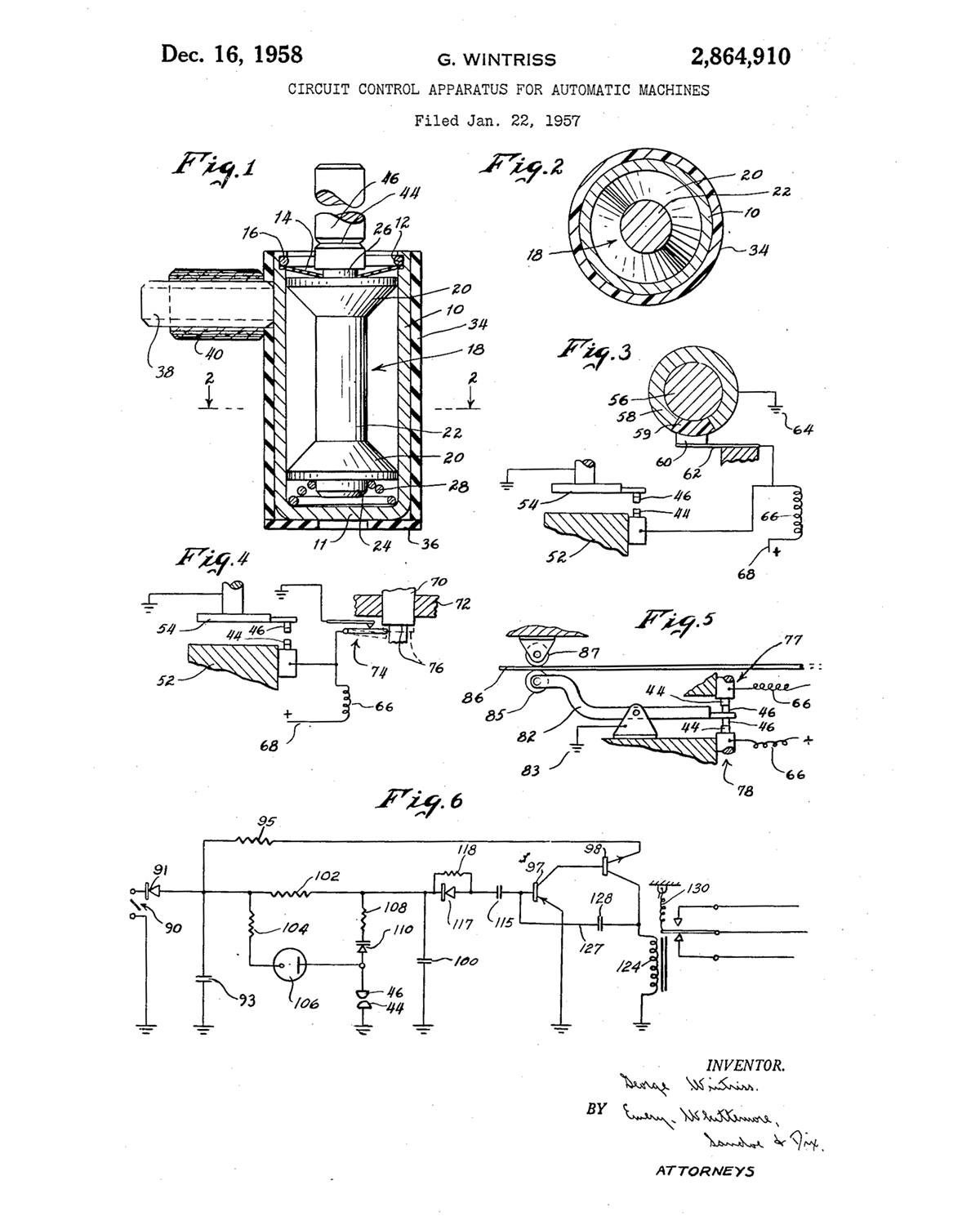

1958 - Wintriss Patents the First Electronic Die Protection System

The drawing below shows the first electronic die protection system patented by George Wintriss in 1958. It includes a drawing of a new sensor, application examples, and even a circuit diagram. This device proved so successful on Wintriss's own presses that the company decided to go into the die protection business, and would shortly offer a comprehensive line of controls, and even began manufacturing electromechanical sensors.

The patent that started it all.

1960 - Wintriss Introduces the Mark III

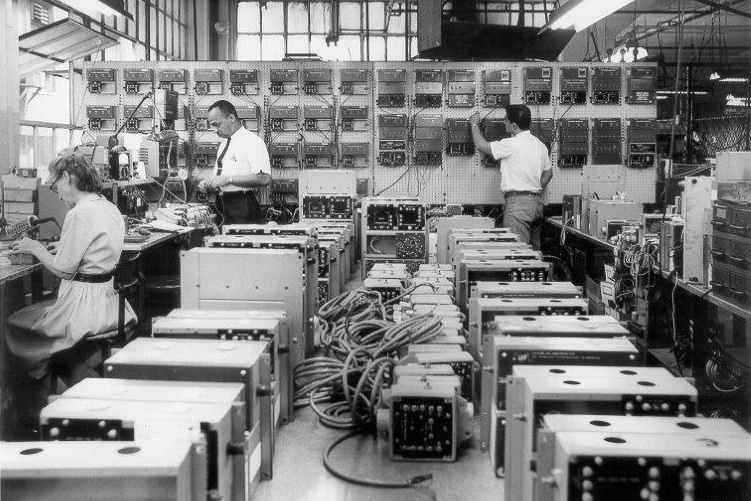

In 1960, Wintriss introduced the first commercially successful solid-state die protection controller, the Mark III. It featured one cyclic and two static (N/O and N/C) inputs. A "transfer" version was later developed that provided additional inputs for more demanding applications. The Mark III was manufactured until 1980.

Mark III Die Protection Control Testing, New York City c. 1963

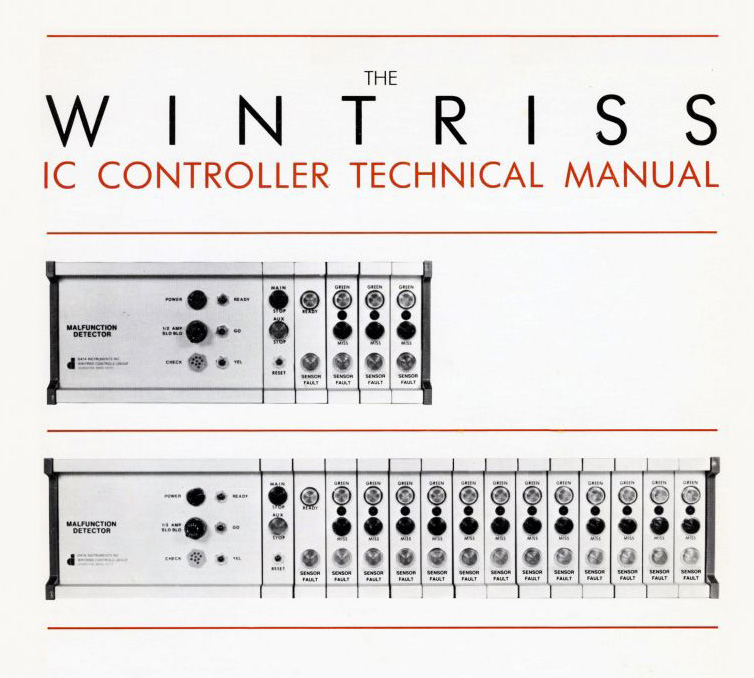

1966 - Tyco Purchases Wintriss Controls - Introduces the IC Control

In 1966, Wintriss was purchased by Tyco. Shortly thereafter, they introduced the first integrated circuit-based die protection system called (appropriately enough) the IC Control. The first version, the IC-3, featured three cyclic and two static inputs. This was later expanded to 12 cyclic inputs with the introduction of the IC-12. The IC Control would be manufactured until 1994.

The Wintriss IC Control was Manufactured for 27 Years

Tyco would later combine Wintriss Controls with Bytrex Instruments to form the Tyco Instrument Division, and relocate both companies to Waltham Massachusetts into the building previously owned by the Waltham Watch Company.

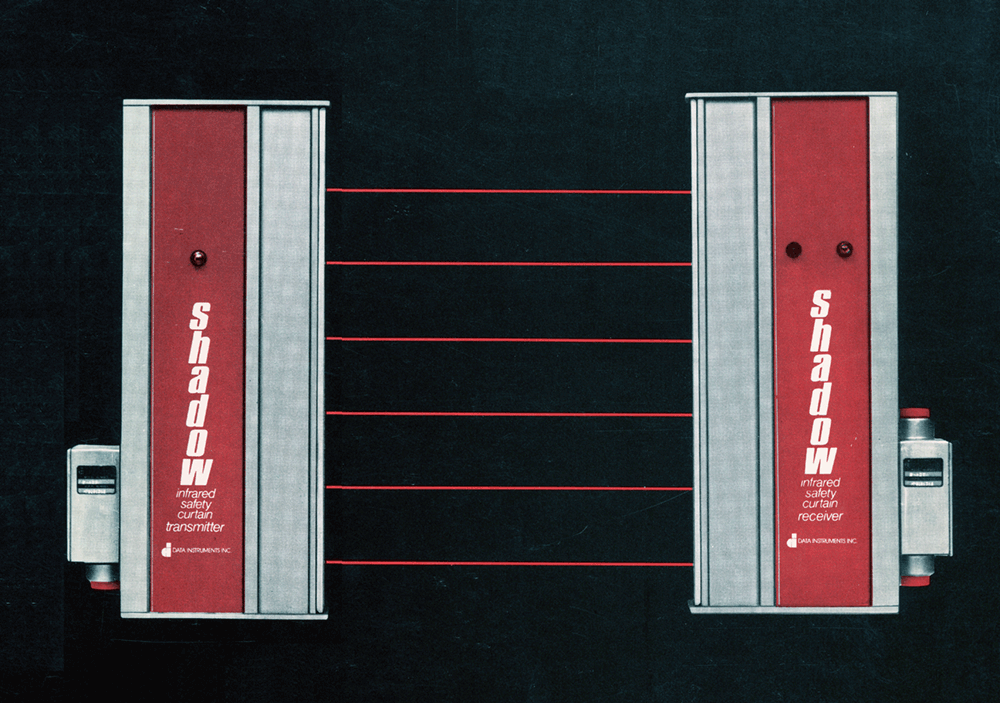

1971 - Shadow® Light Curtain Introduction

Wintriss got into the safety light curtain business in 1971 with the introduction of the legendary Shadow Light Curtain family. After more than fifty years and over 60,000 units installed, the latest generation Shadow 10 continues the tradition of protecting machine operators while preserving productivity.

The Original Shadow Light Curtain

1974 - The First Tonnage Monitor

In the 1960s, Wintriss began research on a method for measuring the load generated by a press. Early attempts included an unusual hydraulic-based tonnage monitor. Wintriss ultimately introduced the Model 701B Peak Strain Monitor in 1974. This device measured frame deflection using electronic strain sensors and displayed load in percent of machine capacity using analog meters. The tonnage limits were set with a potentiometer. Six years later, Wintriss would introduce the all-digital WLA 1000/2000 Series of tonnage monitors, followed by the AutoSet Series in 1989.

The Model 701B Peak Strain Monitor (2-channel version shown)

1977 to 1998 The Data Instruments Years

In 1977, Edward Colbert - the General Manager of Tyco Instrument Division - purchased the Lexington, MA-based division from Tyco and renamed the company Data Instruments. Data Instruments (or DI as the employees called it) continued to manufacture Wintriss-branded controls and a line of high quality pressure and position sensors. In 1986 DI relocated to a new building in Acton, MA where Wintriss continues to operate today.

Data Instruments and its Employees 1986 - Acton, MA

1985 - Wintriss Introduces the Spectrum System

The Spectrum was the first resolver-based "super control". It combined a 16-output programmable limit switch, an (up to) 8-channel tonnage monitor, a 16-input die protection control, a brake monitor, counters, and setup memory into a single microprocessor based control. This ambitious and revolutionary system was a bit "ahead of its time", but was the genesis of the press automation controllers we use today. Along with the Spectrum, Wintriss developed CPR - Computerized Pressroom Reporting, the first shop floor data collection software for the metal stamping industry.

The Spectrum System

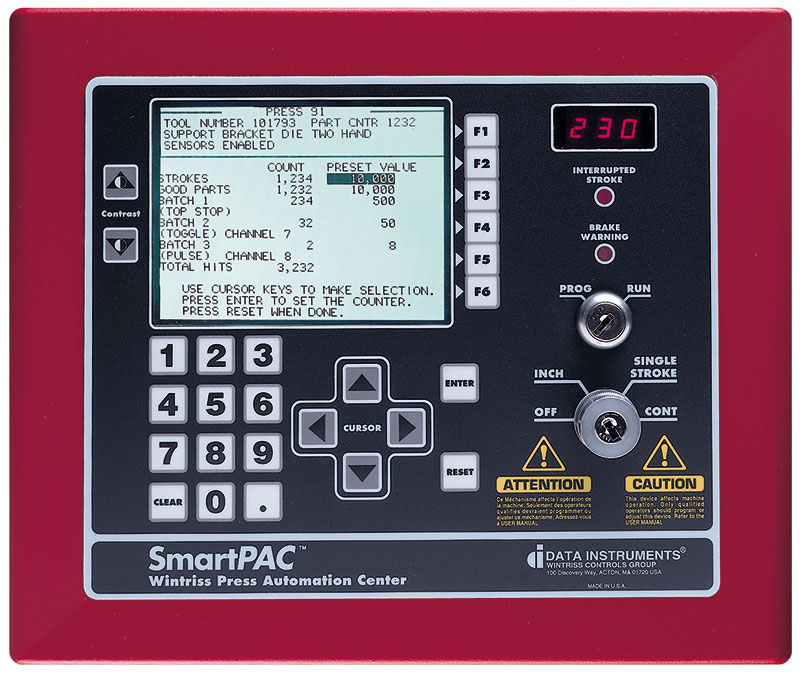

1994 - Wintriss Introduces the SmartPAC Press Automation Controller

In 1994, Wintriss introduced a new flagship press automation controller to replace the Spectrum. In addition to the modules available in the Spectrum, the SmartPAC added integration with the Wintriss Clutch/Brake controller, additional die protection capability and capacity, a tonnage signature monitor, the RamPAC module to automatically set shutheight and counterbalance, the ProPAC Process Monitor for in-die measurement, and a servofeed interface.

Now in its 3rd generation, the SmartPAC PRO features a host of networking and communication features, as well as specific models for Servo and Hydraulic presses.

The SmartPAC Press Automation Controller

1998 - 2009 - The Honeywell Years

In 1998, Data Instruments was purchased by Honeywell International Inc. Under Honeywell's stewardship, Wintriss adopted Six Sigma principles including a company-wide Green Belt program. Wintriss also took ownership of Honeywell's powerful Line Efficiency Tracking Software (LETS) which became the basis for all future data collection software products.

Honeywell-Wintriss, 1998-2009

In October of 2009, Wintriss was acquired from Honeywell by a group of private investors. For the first time in over 40 years, Wintriss was once again an independent company.

2011 - ShopFloorConnect Launched

Wintriss continued to make improvements to the LETS software it inherited from Honeywell. Customer demand dictated that the software be more universal, collecting data and calculating OEE for all types of machinery. In response to this, Wintriss developed ShopFloorConnect Production Tracking Software along with the SMI, a universal machine interface that enables automatic production data logging from any machine in real time (now in its second generation).

The SMI - ShopFloorConnect Machine Interface

The Innovation Continues

In 2019, Wintriss joined the world of eCommerce with The Wintriss Online Store, which offers a carefully curated selection of die protection sensors, controls, and connection hardware specifically selected for metal stamping applications.

In 2021, we released an extensive suite of new features for the SmartPAC PRO DiProPAC including an ultra-flexible cyclic sensor monitoring logic type called (appropriately enough) the Green Flex.

Also in 2021, Wintriss announced a sweeping new feature upgrade for the SmartPAC PRO ProCamPAC Programmable Limit Switch. These new capabilities transform the humble PLS into a powerhouse capable of providing precise timing signals for your most demanding automation requirements.

The Innovation Continues

Wintriss Acquires ISB

On October 1, 2025 Wintriss acquired the assets and intellectual property of ISB ULC and formed a new company in Canada: Wintriss Controls Group ULC, doing business as Wintriss ISB. This merger secures our leadership position in the press safety world and adds ISB's industry best press brake guarding systems to our portfolio.

Wintriss Acquires ISB

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved