100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

Detecting Intermittent Events

Question:

Can I use my SmartPAC to detect an event that occurs once every 5 strokes?

The answer is "Yes". There are two methods to accomplish this. Your application will determine which one you use.

If you only want to ensure that a particular event occurs at least once every "X" cycles, but not necessarily on any one specific cycle, the solution is simple: Install a sensor to detect the event, and make it a "Green Special" sensor type.

Instead of a timing signal, the Green Special sensor uses a counter preset. To satisfy the requirements of the Green Special input, the sensor must turn on at least once during the preset number of cycles.

For example, if you wanted to make sure that a lube system operated at least once every 5 strokes while the press is running, you could install a sensor that would actuate when the lube system operates, set the sensor type to Green Special, and set the counter preset for the sensor to 5. If 5 strokes pass without the system operating, the die protection system would stop the press.

The most common use for the Green Special sensor type is detecting slugs ejected through the bottom die.

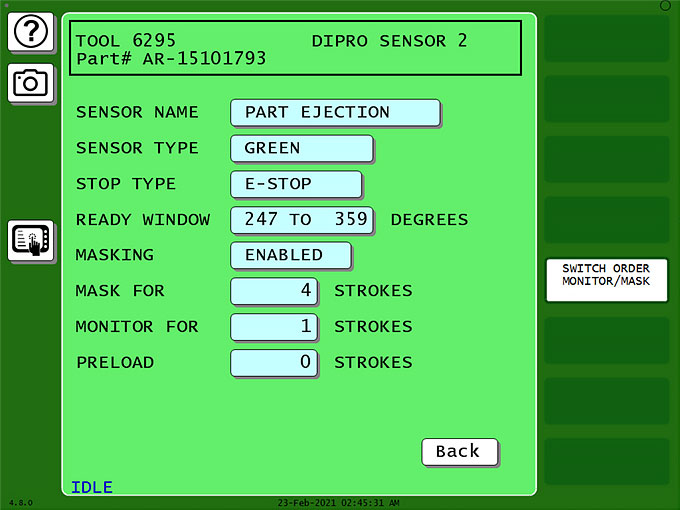

If the application requires the die protection system to verify that a sensor actuation occurs once every "X" number of strokes on a specific cycle, you can use SmartPAC PRO's "masking" feature. An example of an application that would require this would be monitoring part ejection on a die that gagged in a cutoff punch every 5th cycle. You would program the part ejection sensor input as if the part came out every stroke, enable masking, and then set the SmartPAC PRO to mask (ignore) the sensor for 4 strokes, and monitor it on the 5th.

A Green Sensor with Masking Enabled. This look for the part every 5th Stroke

The masking feature is preferred in this application over the Green Special sensor type because the Green Special can only verify that the sensor actuated at least once during the 5 stroke period, and not specifically on the 5th stroke.

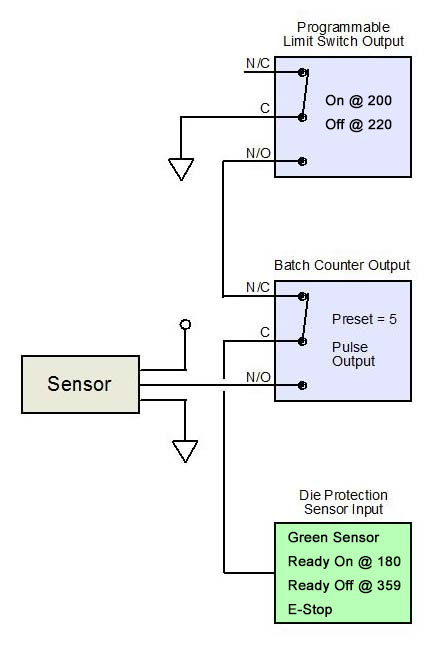

You can monitor this event using the SmartPAC 2, but it requires some additional wiring and programming. It requires the use of both a Batch Counter output and a programmable limit switch in addition to a die protection sensor input. Here's how it works:

First you'll need to program the die protection input to monitor the sensor that detects the part. Let's say that in our example, the part is supposed to pass the sensor somewhere on the upstroke. We would set the sensor type to Green, set the ready signal to turn On @ 180° and Off @ 359°, and the stop type to Emergency Stop. With these settings the part would have to actuate the sensor on the upstroke, otherwise the press will emergency stop.

Simply installing the sensor and programming the input is not enough. The sensor input would be satisfied every 5th stroke when the part comes out, but nuisance stops would occur on the other 4 strokes where it does not. The input has to be 'faked out' on those strokes. This is accomplished using the programmable limit switch and the Batch Counter output.

First, set a programmable limit switch output so that the timing mimics the sensor that we're going so simulate - in this case, On @ 200° and Off @ 220° will get the job done. Then set up a Batch Counter with a preset of 5, set its output to pulse for a duration longer than it takes for the machine to make a complete stroke, and wire everything up according to the diagram below.

Wiring Diagram for Detecting A Sensor Actuation Every 5th Stroke

Here's what will happen:

When the press starts, the programmable limit switch output will be connected to the die protection input through the normally closed contact of the batch counter output.

For the first 4 strokes, the programmable limit switch will connect the die protection input to ground during the ready signal, thus satisfying the input and

allowing the press to run. On the 5th stroke, the batch counter output will actuate, disconnecting the programmable limit switch from the die protection input, and

connecting the sensor directly to the input. During this stroke, the sensor must actuate during the ready signal in order for the die protection system to allow the press to continue to run.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved