100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

Green 'Quick-Check' Sensors

(Where to use them, and when to avoid them)

The term "Green Quick-Check" describes a type of sensor monitoring logic where two conditions must be met:

- The sensor must actuate once per cycle during the specified ready (timing) window.

- The sensor must not actuate anywhere outside of the specified ready (timing) window.

It is named "Quick Check" to differentiate it from a standard cyclic sensor that is only required to turn off momentarily at any point outside of the ready window. If a standard cyclic sensor stays on for a full stroke, the die protection control will stop the machine. The Quick Check sensor will cause a stoppage if the sensor is still actuated at the end of the ready window (in other words, much 'quicker' than a standard cyclic sensor).

When to use a Green Quick Check

The Green Quick Check sensor logic performs two checks - it verifies that the sensor turns on when it should be on and off when it should

be off. It is useful for detecting events that can damage the die if they occur at the wrong time.

The following are examples of the proper application for Green Quick Check sensors:

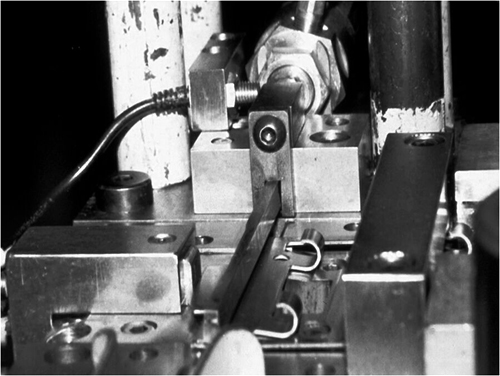

Checking Cylinder Return - The sensor is set up as a "Green Quick Check" sensor type

Ejection Cylinder Monitoring - The proximity sensor in the photo above turns on (actuates) when the cylinder fires (to eject the finished part) and turns off when the cylinder returns. By using a the Green Quick Check sensor logic on this sensor, the die protection system is able to verify that the cylinder fires when the part is ready for ejection, and returns before the die closes.

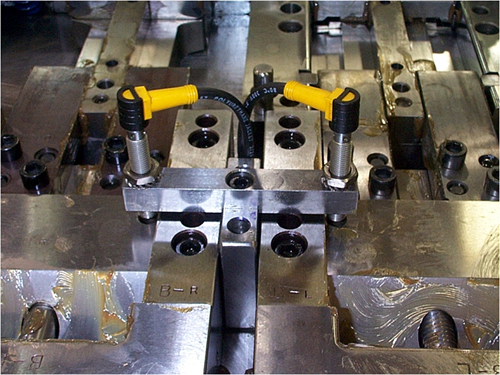

Cam Return is another Green Quick Check application

Side-Action Cam Return - The proximity sensors in the photo above monitors the position of the side action cams. The sensors actuate when the cam is pushed in toward the die, and turn off when the cams return. If either of both cams fail to return, the die protection system can stop the press before the material feeds, avoiding a time-consuming stoppage to remove the mangled strip.

Other suitable applications for this sensor type include monitoring ancillary equipment that moves into the die area on the upstroke, that should not be present when the die closes - such as transfer bars, moving shuttles (to catch parts in a top-knockout operation), and pick-and-place robots.

Where to Avoid Using a Green Quick Check

The Green Quick Check sensor type should not be used in any application where extraneous actuations of the sensor outside of the ready window

are likely to occur during normal operation. Examples include through-beam photosensors for shortfeed detection when the beam is obstructed by

the tooling during die closure, and most part ejection applications - especially when an impact sensor or mini-light curtain is used, as these sensors

are susceptible to false actuations outside of the ready window.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved