100 Discovery Way, Unit 110, Acton, MA 01720 US.

Mon-Fri, 8:00 AM - 5:00 PM (GMT-5)

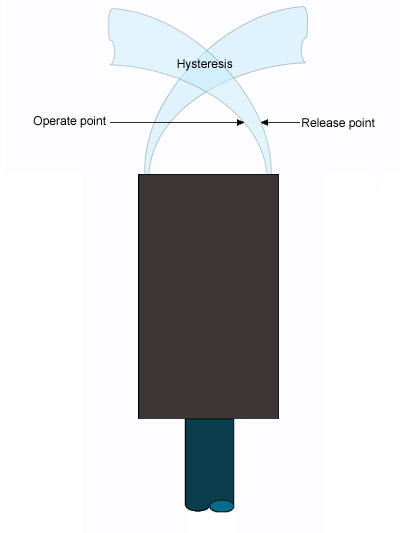

Proximity Sensor Hysteresis

In the context of sensors and switches, the term 'hysteresis' refers to the difference between the 'operate' and 'release' point.

Hysteresis can be demonstrated very easily using a snap-action micro switch. If you carefully and slowly move the actuator on the switch until you feel it actuate, then reverse direction and slowly release the actuator until the switch turns off, you'll notice that there's certain amount of travel between the two points. This difference between the operate and release points is the switch hysteresis. In the case of a micro switch, it is mechanically controlled, and intentionally built into the design. Hysteresis also exists in proximity sensors, and it is also an intentional product of the sensor design.

Some hysteresis is necessary in most control systems - the classic example of which is the thermostat controlling your home furnace. If you set the thermostat to 70°, the furnace might not turn on until the temperature drops to 68°; and it will stay on until the temperature reaches, maybe 72°. Without this built-in hysteresis, the furnace would try to turn on as soon as the temperature dropped below 70°, and turn off again as soon as 70° was reached. If it operated in such a manner, it would constantly be turning on and off, wasting energy and requiring much more frequent maintenance.

Proximity sensors' hysteresis prevents them from rapidly turning on and off (chattering) if the target object is right at the operating threshold point of the sensor. The amount of hysteresis varies with the distance between the target and the sensor. There is more hysteresis at a greater distance from the sensor (see Figure 1 below)

Proximity Sensor Hysteresis (Light blue shaded area)

Hysteresis can cause application problems when a too-large proximity sensor is used to detect a small hole. A proximity sensor's sensing field is shaped like a rounded cone - the sensing field becomes smaller in diameter as the target-to-sensor distance increases. Some users attempt to take advantage of this fact by trying to use a large sensor to detect a small hole simply by backing the sensor away from the target. The theory being that the increased target-to-sensor distance will place the small diameter portion or the sensing field into the hole, allowing it to be detected.

This method will work if the target approaches the sensor head-on, but if the target approaches the sensor from the side (as it does in most stamping applications), the hole will not be detected by the sensor unless the hole diameter is larger than both the sensing area as well as the extended area covered by the 'release' portion of the hysteresis curve.

This problem can be avoided by selecting a sensor with a sensing field that closely matches (but is slightly smaller than) the hole diameter, and installing the sensor as close to the target as possible.

© Copyright 2021 Wintriss Controls Group LLC - All Rights Reserved